Cincinnati

230 AS X 10 FT

230 ton x 10'

3/60/208

45008

Control Cabinet, "autoshape", 10" Stroke, *contains 2 Pieces 0520-037-0001

chat Contact Us circle

Chat with a sales rep to purchase a product, ask questions, or for technical support. You can also fill out a form and submit an inquiry.

About This Item

Product Overview

The Proform+ has dual pressure transducers on its hydraulic cylinders for increased tonnage accuracy, and digital encoders to deliver 0.0004" (0.01 mm) ram repeatability for close-tolerance forming and higher part quality.

The press brake's PC-based control is now bed-mounted to the machine with a swinging pendent arm mount, and has been upgraded to include a trackball and keyboard. An optional Wila crowning system compensates for bed and ram deflections during bending, and eliminates the costly trial-and-error approach used in traditional die shimming. Available Proform+ models include 90- to 350-ton capacity and overall bed lengths from eight to 16 ft.

The Proform+ includes numerous premium-engineering features that ensure reliable, long-lived operation. Clevis-mounted cylinders and centerline loading confine operating stress to the main housing, eliminating cylinder misalignment. The Machine's Variable Volume Load Sensing (VVLS) hydraulic system lowers maintenance costs and increases energy efficiency. Hydraulic cylinders use hardened piston rods with precision guiding to minimize oil leaks, and the machine's heavy plate frame is precision machined and rigidly interlocked – not welded – to better resist deflection for years of precision forming at maximum loading.

The Proform+'s powerful, PC-based control combines 3D graphics interface with simple touch-screen operation to speed setup and programming times, as well as optimize throughput. New part programs can be generated through manual data entry or by drawing the part in cross-section or flat pattern, and then selecting tooling and bend sequence. A special job setup page displays tool segment lengths and tool locations, as well as notes to improve part consistency.

The Proform+ is available with a variety of tool holders, filler blocks and clamps to accommodate most major tooling types, including American or European-style tooling. The new press brake includes a standard bolt-on manual quick clamp or optional bolt-on hydraulic clamps to accommodate major manufacturers' die designs. Both clamps dramatically reduce setup time. An optional 5-axis backgage – with fast positioning speeds, flip backgage fingers with hardened dowel pins, 40-inch gage points and auto flange correction – handles a variety of complex parts. In addition to the new Wila crowning system, the Proform+ is also available with CINCINNATI’s Auto Crown, an automatic, hydraulically-powered crowning device that can produce angles within ±1/2° variation along the bend line. All Proform+ models have a quick-access emergency-stop button in the center of the operator station, with an additional palm button and footswitch available for two-operator jobs.

Product Features

• Touchscreen Human Machine Interface

• Optional Bend Simulation Software (offline)

• Graphical Tool Library and Part Views

• Optional Backgages up to 5 axes

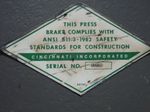

• ANSI B11.3 Compliant

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Video

Buy From A Trusted Seller

With a stellar 4.4 star rating and hundreds of reviews, we've earned the trust of companies globally.

Browse EquipmentName Your Own Price

Submit offers on any item over $250. We will promptly review, accept, or propose a fair counter.

Learn How to Make an OfferDelivery Nationwide and In-Store Pickup

Benefit from our global delivery options, bringing your equipment to your doorstep, or pickup in-store at your convenience.

How Delivery Works30-Day Money Back Guarantee

Join HGR for free today and enjoy benefits like 30-day hassle-free returns and flexible purchase options.

Become a HGR Member for FreeTestimonials

“I absolutely love this place. This is Disneyland for an automation guy like me. The service was beyond great and Danny, Maxwell, Chris and Ernesto make an awesome team. I personally picked up a robot cell in Forth Worth then drove to Ohio and picked up a SCARA robot and welder system that I got for a really good price! I will definatley be back for more.... thanks guys at HGR!”

“UNBELIEVABLE SELECTION! [Sales rep] was great, he took the time walk me and my son around the showroom and was very knowledgable. I will definitely return when my budget permits.”

“They have just about any type of equipment that you could possibly want. And the sales representative was awesome to deal with.”

“It's a playground of used equipment that you can buy whole or salvage parts off of.”

Translated: “Excellent! Place has a great variety of products! At very cheap prices!”

“Out of this world”