Sold

This item has been SOLD.

Inventory No.

0321-070-0001

Manufacturer

Fanuc

Model No.

M-16i

Dimensions L x W x H (inches)

Unavailable

Capacity

-

Electrical

-

Weight (lb.)

4880

Category

Condition

See Details

Quantity

1

Serial No.

R99476614

Make Year

1999

Item Details

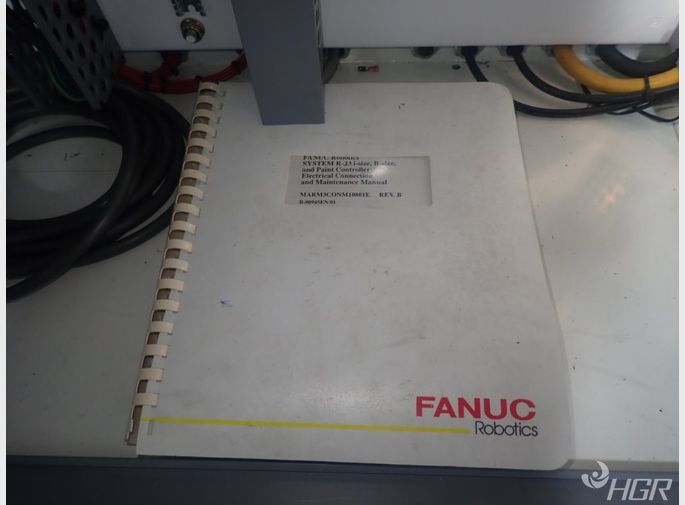

W/control, Pendant, Branson Ultrasonic Welding Power Supply, A05b-1212-b202 Robot, A05b-2403-b004 Control, A05b-2301-c301 Pendant, *contains 2 Pieces 0321-070-0001

About This Item

Product Overview:

The FANUC M-16i and long-arm M-16iL robots are engineered for precision, high-speed operation, user-friendly setup and maximum reliability, supported by our extensive service and parts network. The M-16i is a six-axis, modular construction, electric servo-driven robot designed for a variety of manufacturing and system processes.

M-16i, the Solution for:

• Assembly

• Dispensing

• Material handling

• Machine load/unload

• Material removal

• Waterjet cutting

Benefits:

• Large work envelope and load capacity allow robot operation in a wide range of high-speed, medium-payload manufacturing processes.

• Double-jointed” arm ncreases work envelope and positioning flexibility.

• No robot modification required for upright, inverted, angle and wall mounting.

• Absolute serial encoders eliminate the need for calibration at power-up.

• Unique hollow RV speed reducers simplify cable routing.

• Small footprint facilitates placement in tight surroundings.

• Low arm mass and rigid design allow high-speed, precise positioning.

• Electrical and pneumatic services for tooling are internal to the arm to simplify integration.

• Fail-safe brakes on all axes increase safety, functionality and control.

Product Features:

• 6 axes of motion

• 16 kg payload capacity

• 0.08 mm repeatability

• Axes speeds up to 450° per second

Reliability:

• Sealed bearings and drives, and brush less AC motors minimize maintenance.

• Grease fittings on all lubrication points for quick and easy maintenance.

• Uses directly-coupled drives, which are more reliable than belts, pulleys or chains.

• All motors, cables and tooling services are engineered to prevent snagging and damage from chips, sprays and other

• hazards.

• Dust and water resistant design maximizes durability.

• Quick disconnect robot connecting cables.

• In-line wrist design minimizes complexity and eliminates bevel gear adjustments.

Options:

• Axis 2 motor cover

• Severe dust and liquid protection package for die cast spray, waterjet cutting and other harsh environment applications (standard M-16i wrist is rated IP67 to withstand temporary immersion in liquids).

General:

Manufacturer: Fanuc

Model Name: Robot Ultrasonic Weld Cell

Model Number/MPN: M-16i

Inventory Number: 0321-070-0001

Series: R99476614

Make Year: 1999

Specifications:

Aisle: 04A

Bay: 1600

Weight (lb): 4880 lbs.

Axes: 6

Payload (kg): 16

Reach (mm): 1605

Repeatability (mm): ±0.08

Interference radius (mm): 312

Motion range (degrees):

J1: 330

J2: 240

J3: 455.5

J4: 400

J5: 280

J6: 900

Motion speed (degrees/sec.):

J1: 140

J2: 140

J3: 140

J4: 330

J5: 330

J6: 450

Wrist moment(kgf m):

J4: 3.6

J5: 3.2

J6: 1.6

Wrist inertia (kgfcms2):

J4: 8.7

J5: 7.1

J6: 2.0

Mechanical Brakes: All Axes

Mechanical Weight (kg): 270

Mounting Method: Floor, Ceiling Angle and Wall

Temperature degree C: 0 to 45

Humidity Normally: 75% or less Short term Short term (within a month): 95% or less 95% or less No condensation

Vibration (m/s2): 4.9 or less

IP Rating(s) Body IP54 std. (IP55 optional) Wrist & J3 arm IP67 Wrist & J3 arm IP67

Payload at axis 3 (kg): 20