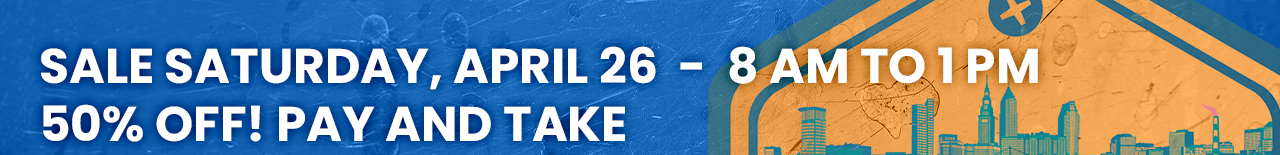

Carnival of Savings on Saturday, July 12, 2025, doors open at 8 a.m. and close at 1 p.m.

All in-store purchases on Saturday, July 12, 2025, will give customers one chance to win a CASH PRIZE! One chance per customer only.

1 Grand Prize winner will receive a $2,500 check

5 Secondary Prize winners will win a $500 check

The following discounts are for Walk-ins Only! You MUST be in-store to get the discount. Items MUST be inventoried before March 15, 2025

50% off (pay and take) for all items priced at $499 or less

30% off all items $1,000-2,999

20% off all items $3,000 or more.

FREE Breakfast burritos by Jackpot Chicken Food Truck!

The first 50 purchases could win an extra discount!

Watch the final episode of the Saturday Sale Saga below.

$999 or less will receive 50% off current website price

$999 or less will receive 50% off current website price

As technology grows and increases, the need for new and advanced technology increases as well. If you own any type of business, you are always on the lookout for the newest products. A product hot on the market right now are touch panels. An Australian company called Commbox has many different styles of these panels that are perfect for all different needs. These touch screens not only help a select few businesses but can be of advantage to anyone. This product with the newest technology is ensured to be of use to you.

As technology grows and increases, the need for new and advanced technology increases as well. If you own any type of business, you are always on the lookout for the newest products. A product hot on the market right now are touch panels. An Australian company called Commbox has many different styles of these panels that are perfect for all different needs. These touch screens not only help a select few businesses but can be of advantage to anyone. This product with the newest technology is ensured to be of use to you.

If you work with or have anything to do with machines, you can understand how important the machine industry is. Industrial Machinery is incredibly important for every aspect of America, and all across the world as well. Whether you are looking for brand new machines or used machinery, this blog will highlight what some important machines are and how you can purchase them.

If you work with or have anything to do with machines, you can understand how important the machine industry is. Industrial Machinery is incredibly important for every aspect of America, and all across the world as well. Whether you are looking for brand new machines or used machinery, this blog will highlight what some important machines are and how you can purchase them. Everyone loves buying products brand new – they are ready to use. Though, there is something nice about building or making your own objects. Plus, it can be cheaper to make something yourself! If you are looking for something useful and fun to create, this blog is perfect to read. HGR sells a very basic material that you can make many useful products out of. This material is a Pallet Rack Wire Deck. Listed below are some awesome products you can make yourself out of wire decking.

Everyone loves buying products brand new – they are ready to use. Though, there is something nice about building or making your own objects. Plus, it can be cheaper to make something yourself! If you are looking for something useful and fun to create, this blog is perfect to read. HGR sells a very basic material that you can make many useful products out of. This material is a Pallet Rack Wire Deck. Listed below are some awesome products you can make yourself out of wire decking. Cincinnati Incorporated

Cincinnati Incorporated

Swissturn CNC Lathe Auction at HGR. Auctions are a great way for customers to get working used equipment for less than buying new machinery. Machinery can be expensive when looking at the initial investment and for some start up companies this may not be an option. Machinery auctions are something that many people may not be familiar with. I. Some cases business may be closing their doors and looking to recoup their investment. Other times they have upgraded machines and the old one is still in great condition and running. Moving these machines can be time and labor intensive, so posting these machines for auctions while still in their location and under power is advantageous to most sellers and buyers. Being able to see where the machine was housed and it in action invaluable to a potential buyer. Each auction has its own treasures to find, so check back frequently with HGR on the

Swissturn CNC Lathe Auction at HGR. Auctions are a great way for customers to get working used equipment for less than buying new machinery. Machinery can be expensive when looking at the initial investment and for some start up companies this may not be an option. Machinery auctions are something that many people may not be familiar with. I. Some cases business may be closing their doors and looking to recoup their investment. Other times they have upgraded machines and the old one is still in great condition and running. Moving these machines can be time and labor intensive, so posting these machines for auctions while still in their location and under power is advantageous to most sellers and buyers. Being able to see where the machine was housed and it in action invaluable to a potential buyer. Each auction has its own treasures to find, so check back frequently with HGR on the