New Arrival

C & G Systems / Thermadyne Challenger CNC Plasma Cutter

Shop for C & G Systems / Thermadyne Equipment

Sold

This item has been SOLD.

Inventory No.

0820-128-0008

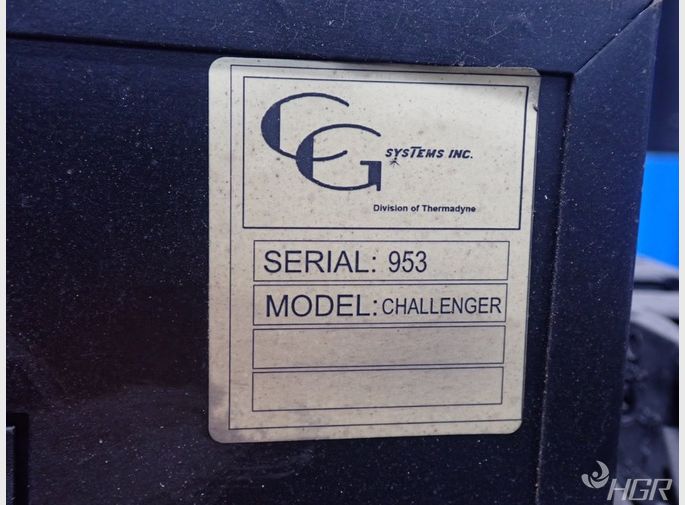

Manufacturer

C & G Systems / Thermadyne

Model No.

CHALLENGER

Dimensions L x W x H (inches)

Unavailable

Capacity

54" X 54"

Electrical

-

Weight (lb.)

3760

Category

Condition

See Details

Quantity

1

Serial No.

953

Make Year

1999

Item Details

Burny 3 Control 0820-128-0008

About This Item

Product Overview:

Versatile and Expandable:

The Challenger is your best value for high-production conventional or precision plasma, as well as heavy duty oxy-fuel cutting applications. A time-proven design featuring sturdy, long-lasting components will boost your production to new levels.

CNC Controls:

Challenger DSD is available with Hypertherm EDGE-Ti, EDGE-Pro, Burny 10 LCD+, or Thermal Dynamics XT CNC Controls. These industrial PC-based controls run in a user-friendly yet powerful Windows XP environment and have 15” TFT touch-screen monitors.

Heavy-Duty Construction:

The new Challenger DSD series builds on the time tested Challenger platform. A powerful dual-side drive system replaces the traditional single-side drive, and rides on precision machined and hardened tongue-in-groove 90# T-Rails mounted on 6” x 8” (150 x 200 mm) steel tube pedestals. To ensure a smooth and accurate motion, crowned truck wheels with self-cleaning wipers are used.

Challenger DSD also features new Clean Deck design, which provides maximum protection for cables and hoses, while providing easy access for routine maintenance and service.

Plasma Productivity:

A variety of integrated torch height control systems from Hypertherm, Inova, and Thermal Dynamics are available to meet the demands of high-volume production. Pierce heights are accurately set prior to each arc start and torch-to-plate distance is precisely maintained during cutting. These systems utilize fast response servo motors for optimal cut quality. Challenger DSD can be equipped with a wide variety of conventional or precision plasma systems up to 400 Amps from Hypertherm, Kaliburn, or Thermal Dynamics for production cutting capacity of up to 2” in steel, 2.3” in stainless, and 3” in aluminum.

Oxy-Fuel Performance:

Challenger DSD can be equipped with up to 4 oxy-fuel stations. Heavy-duty high performance oxy-fuel components are your guarantee of superior productivity. The optional gas system includes twin sets of high and low pre-heat regulators to produce fast pierce rates and balanced torch flames, even with multiple torches. A domed high-flow oxygen regulator provides adjustable pierce rate control and outstanding flow capacity. The standard Victor MT318 torch is designed for cutting plate up to 12” (300 mm) thick.

Challenger DXD:

C&G Systems has designed its DXD series of machines around Hypertherm’s Rapid Part and True Hole Technology processes. By seamlessly integrating the full suite of genuine Hypertherm Edge Pro CNC controls, ProNest software, ArcGlide torch height controls, and XD plasma systems, superior hole quality and significant improvements in productivity are achieved. True Hole Technology automatically optimizes system settings to produce superior hole quality, often eliminating the need for secondary operations. Rapid Part intelligently retracts the torch to next pierce height with rapid Z-axis motion, pre-flows gases during IHS or during machine motion, and optimizes motions between cuts.

Product Features:

Up To 5 Plasma and Oxy-Fuel Cutting Stations

Plate Marking Station

Fiber-Optic or Wireless Communication Package

Air Exhaust or Water Cutting Tables

Heat Shields

Exhaust Systems

Dedicated Air Compressors & Dryers

General:

Manufacturer: C & G Systems / Thermadyne

Model Name: CNC Plasma Cutter

Model Number/MPN: CHALLENGER

Inventory Number: 0820-128-0008

Series: 953

Make Year: 1999

Condition: Used

Specifications:

Aisle: 14A

Bay: 2800

Weight (lb): 3760 lbs.

Capacity: 54 x 54 in.